If your bike is starting to suffer from blown headlight bulbs or the battery’s ability to hold a charge is becoming unpredictable then you need to inpect your bikes charging system.

There are three main sections to the charging system on most bikes (excluding the wiring inbetween). Those are the Battery, Regulator/Rectifier (R/R) and the Stator.

The battery is there to power the electrical components of the bike when the engine is not running.

The job of the Stator is to convert mechanical energy from the engine back into electricity. The output from the stator on most modern bikes is three phase (hence the 3 wires) alternating current at a peak voltage well over the 12-14V DC voltage that your electrical system requres.

The R/R unit converts the alternating current (AC) in the diode bridge rectifier section then regulates the voltage to limit it to around 14V DC where it is fed back into the Battery and powers the rest of the bikes electrics.The voltage is higher than the battery voltage so current flows from the R/R unit back to the battery to charge it.

First off before you go running through the following tests, if you are having any electrical/charging problems then check that all electrical terminals/connectors are all tight, free from corrosion and secure. Also inspect for signs of either breaks or burning in the wiring or connectors.

To do a thorough test of the charging system or other electrical items you will require the use of a Multimeter and/or a 12v Test Light. A Multimeter if used correctly is going to give you more accurate results where as a test light will only give you an approximate result according to either the brightness of the bulb or if the bulb lights up or not.

1. IGNITION OFF

2. IGNITION ON, LIGHTS ON, BIKE NOT RUNNING

3. BIKE STARTED, LIGHTS ON, RUNNING AT FAST IDLE

4. FURTHER TESTS, IGNITION OFF

5. RESISTANCE TEST

6. VOLTAGE TEST

7. CURRENT DRAIN TEST

1. IGNITION OFF

First test the condition of the Battery. With the Battery on the bike and connected and set your Multimeter to 20v DC. Your basically setting the meter to the next nearest number that covers the maximum range that you are testing for. Put the Red probe on the the positive (+) terminal and Black to negative (-) earth terminal and check the initial Battery voltage. It should read anything above 12.0v but under 13.2v but ideally between 12.5 – 12.9 DC volts is required. Any less than this, you may start to encounter starting problems as the Battery will not have enough juice to turn the big twin motor over. Most of the battery power is required for cranking the engine over from cold.

If the Battery is flat then use an Optimate or similar slow charger to recharge the battery. The Optimate chargers also benefit from a recovery mode. The slower the charge the better it is for the Battery long term. Do not use a car charger as it will shorten the life of the Battery and overheat the internal fluid and cells. You should disconnect the Battery if not using the bike for long periods of time and put it on trickle charge. Batteries do discharge slowly over time and it is not always possible to recover a fully discharged Battery.

2. IGNITION ON, LIGHTS ON, BIKE NOT RUNNING

With the Battery fully charged and functional it’s time to test for Battery voltage drop. With the Multimeter on the same settings as above. With the ignition on and the bike not running switch on the lights and you should see the voltage drop slowly as the lights use up the power in the Battery. The voltage should not drop much below 12v and should only decline slowly. If the the voltage drops rapidly to around 11v then the Battery has either not been charged thoroughly or it is not holding a sufficient charge and will need replacing.

3. BIKE STARTED, LIGHTS ON, RUNNING AT FAST IDLE

Now on to testing the main charging function, the voltage output from the Regulator. Test the voltage with the bike running at fast idle, roughly between 2000 and 5000 rpm, to confirm if it is getting the correct amount of charge from the bike. With the Multimeter set to 20v DC place the meter leads across the Battery as before, if all is healthy you should be getting between 13.5-14.5 volts, an old or tired Battery will be around 13.2 – 14.8 volts if undercharging or overcharging but is of no great concern as of yet, but keep a close eye on things over time to make sure it does not deteriorate. Please note that these voltages will fluctuate depending on temperature and revs.

Rev the bike and the voltage should be at least in the 13’s at all engine rpm’s and go no higher than around 14.5v. If you are reading 15v or higher it is bad and means that the R/R is not regulating the extra voltage from the Stator and overcharging the Battery. This will start to boil the fluids inside the Battery dry and will eventually leave you stranded as the battery will not be able to hold a charge.

If this is the case then it is likely that you will have to replace the Regulator/Rectifier and the Battery. This also works the opposite way. If the Battery is defective, either dried out or has damaged cells from age or electrical faults, the Regulator will output the maximum it can trying to charge the Battery back up. If this continues for long periods of time then it can eventually damage the Regulator though heat damage with having to dissapate excess voltage rather than charging the battery. So yet again it is likely that you will have to replace the Regulator/Rectifier and the Battery.

Be warned, don’t just go out and replace either one or the other without checking the other is functioning correctly first. Otherwise you could be just treating the symptom and not the cause and get caught in a cycle of either one or the other breaking your replacement. This could get expensive.

But hold on…. before rushing out and buying replacements the earth to ground should be checked and ruled out from causing any misleading readings.

The R/R will be earthed to ground either by the mounting to the frame or a separate wire. A separate wire being the more common of the two. It’s very important to have a good solid earth as the Regulator will shunt (short) any excess alternating current (AC) from the Stator before giving the Battery the required amount of direct current (DC) . This is why R/R units get very hot as the internal diodes switch on and off to ground as they pass high amounts of current through them. Excess shunting due to an unhealthy battery puts additional strain on the Stator which can result in the coils burning out!

To test that that there is a good earth check and clean up all connections, it’s a good idea to use a serrated type washer that digs in to the surface when tightened after previously removing any paint or powdercoat. Either bare metal or a direct feed to the Battery will give the best connection. Once your are sure the earth is good run through the above voltage output test again. If the earth is ruled out and is all good, yet your still getting above 15v then it’s time for either a replacement R/R Unit, Battery or both.

With the bike running, lights on, and as you rev the bike the lights should get a little brighter as the Regulator puts more voltage back into the Battery to charge it. If the voltage does not rise at all and the lights don’t get any brighter then there could be a fault with the positive (+) feed to the Battery via the main fuse, so don’t rule out connections on the Starter Relay behind the left rear fairing or even the Ignition Switch itself.

Then if you are getting a normal charging voltage but when you rev the bike harder the voltage drops, even down to zero, then the Regulator/Rectifier is breaking down under load and will need replacing. You can also do a quick load test with the ignition on with the bike not running and applying the brakes. The Battery voltage should drop no more than around 1 volt with the brakes applied.

4. FURTHER TESTS, IGNITION OFF

Do a leak to ground test, with the ignition off. Start with either disconnecting the plug from the R/R or the 3 pin connector block further down that leads to the Stator. This can be found in the main wiring harness connector bundle in front of the Battery and has three Yellow wires going into it.

Test each wire individually with your multimeter set 20v DC put the Red positive probe on each connector either directly on the R/R outputs or if working from the connector block in the harness, on each connector pin on the R/R side. Then put the black negative probe to earth either on the engine frame or Battery and check to see if the meter is reading any excess current leakage.

If you have any more than a couple of volts then the diodes inside the Regulator are faulty and allowing voltage from the Battery to leak to earth. This will also allow current from the Stator side to leak to earth so it won’t be providing the full amount.

The same test can also be done on the R/R earth wire or the body of the R/R itself. To do this you will have to disconnect the R/R from the frame and disconnect the earth from either the frame or the Battery if you have it connected direct. Place the Positive meter probe either on the body of the R/R or earth wire and the negative probe to earth. Again, if there is more than a couple of volts then you have a problem.

5. RESISTANCE TEST

Next it’s time to do a resistance test for no continuity between the Stator coils/windings. This can be done from the same 3 pin connector block in the main wiring harness connector bundle in front of the Battery, only you will use the opposite end of the plug that goes back towards the Stator, or you can take the reading from the R/R connecting block leading back towards the 3 pin connector and on to the Stator.

First turn your Multimeter to the lowest Ohms scale, mine is 200, then touch the probes together to get a resistance reading from the meter. My meter reads 00.2 yours may be a different reading depending on the meter used. You have to remember this number as it needs to be deducted from your final reading later.

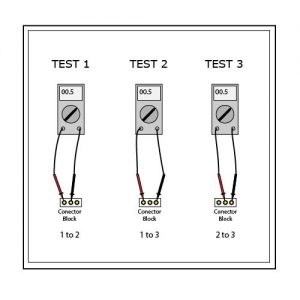

With engine off and the connecting block disconnected from either the Regulator/Rectifier or the 3 pin block, test the resistance on each of the three Yellow wires in the following combination 1 to 2, 1 to 3 and 2 to 3 as in the following diagram.

For each test the meter should read between 0.2 and 0.5 ohms. If you have no resistance or a high resistance between any pair then you need to pull the Stator out and visually inspect it for any burnt sections. If a third or more of it is damaged then it’s time for a replacement Stator. There may be enough to keep the bike running, but as soon as you use more Battery power up with lights or accessories the Battery will slowly discharge until it eventually dies.

Also test the three Yellow Stator wires for a short to ground/earth. Connect the positive meter probe to one of the three stator connections in the plug and the negative to earth. If you meter reads either a 1 or I followed by a decimal point then this is an Infinite resistance, meaning no path to ground/earth which is what we want. If you have any other reading then one of the Stator coils/windings is grounding out and will not produce as much current as it could and loose the ability to charge the Battery. Do the same test on all three wires.

6. VOLTAGE TEST

Even if Resistance is all good you can still have a faulty Stator as a Stator can pass the resistance check but fail a voltage check. A voltage output test will show up if it’s producing a reliable current throughout the rev range.

For this test you need to set your multimeter to an (AC) alternating current voltage of a minimum of 100v AC depending on how far you test, the lowest setting on my meter is 200v AC which is more than enough. With the bike running and connector block disconnected measure the AC voltage between each of the three Stator connector terminal pins as in the previous resistance test as per the diagram above and make a note of what they read. You will have around 20v AC or thereabouts at 1000rpm depending on the amperage of the bikes charging system.

The actual voltages measured is not so important and they will vary depending on revs. But what is important is that the three measured voltages are roughly the same value. A reasonably safe tolerance would be around -5 or +5 of each other, any more than this would suggest a short in the Stator coils/windings and further investigation would be required. Also check the voltage throughout the rev range as it should rise in increments the higher the revs. For example, at 2000rpm it should read around 40v AC, so double the amount of what it read at 1000rpm, then at 3000rpm is should read around 60v AC, 4000rpm it should be 80v AC and so on. If there is a weak output or no output at all then there is a problem with Stator at higher revs and further investigation is required.

For a thorough test the Stator resistance and voltage checks should both be done when the engine is cold and also when the bike it is at full running temperature. This ensures that you don’t miss any faults that may only show themselves either when cold or hot from the expansion and contraction with temperature.

If you are positive that the fault lies within the Stator itself then it will require the removal of the generator cover. Check the Stator for any loose windings, broken wires or signs of overheating and burning.

7. CURRENT DRAIN TEST

If all above tests prove to be sufficient and you can’t find a fault within the charging system and are suffering from a Battery constantly discharging, it could be one of two things. First you either have a defective Battery.

Sometimes a Battery can pass all tests but they can fail in many ways and faults don’t always show up when testing. Or second, you have some other component that is drawing current from the bike especially when everything is switched off and the bike is sitting overnight. Alarms or immobilisers can be off particular concern here.

A quick test would be, with the ignition off, disconnect the Battery positive cable being careful not to touch the frame with your spanner, or temporally disconnect the negative/earth first. Connect a 12v test light between the positive cable and the Battery positive. If the light comes on then you have something drawing power. The brighter the light, the more power being drawn. To try and determine which circuit the power is being drawn from, disconnect the fuses one by one until the light goes out or dims. You would have then narrowed it down to only the components within that particular circuit and can investigate further.

A more accurate test would be to use a multimeter set to direct current amps, not volts. You may have to move the positive probe to a separate socket on the multimeter. Sometimes there are two sockets, a high range and a low range. Always test on the highest setting first, the highest setting on your multimeter will more than likely be 10A Max. The low setting will be in milliamps indicated as mA or uA. If by testing on the highest setting first and the current draw is less than the multimeter’s next lowest setting, then it is safe to proceed with moving the positive probe back into the other socket and keep testing.

Do not start the engine while running this test or put the probes across both Battery terminals or you risk either damaging the multimeter or blowing it’s internal fuse. To start the test first disconnect the Battery negative/earth cable. With the ignition off and starting with the highest setting on the multimeter, place the positive meter probe on the cable and the negative probe on the negative on the Battery. You will then see any current draw. Where possible select the next highest setting down such as mA or uA and move the positive probe to the appropriate socket on the meter. This will change the readout from amps to milliamps and give the most accurate reading for a small current draw. The specified current draw as standard is 0.01mA . As long as you don’t have items on the bike connected to a permanent Battery feed and switched on like alarms, immobilisers, LED’s or something then this should not change, otherwise the reading will be slightly higher but should be no more than around 0.03 depending on how many items you have running.

If you have a high current drain then remove the fuses one by one as before until the current drops to narrow down which circuit the current is being drawn from. An alternative way to run this test would be from the fuses themselves by placing the probes directly across each side of the fuse on the circuit being tested.

I think that just about covers it.

Al.